Innovative Rotomolding Materials: Pioneering the Future of Plastics

Perhaps you have came across plastic items that are durable, lightweight, and spending budget-helpful? Chances are they may be rotomolded items. The process of rotomolding consists of molding a hollow plastic-type product by home heating a plastic materials in a fungus. In this post, Plastics Rotomolding we will delve further into the ability of making plastic material goods and just how rotomolding has made an important impact in the developing business.

1. What exactly is Rotomolding?

Rotomolding, also referred to as rotational molding, is really a plastic-type material developing procedure that creates hollow plastic material products. The procedure necessitates the home heating of your plastic fabric, usually polyethylene, in the mildew that is rotated on two perpendicular axes, thus evenly distributing the melted plastic-type. This generates a higher-top quality and regular done product or service. Rotomolding is ideal for making complex forms conference the exacting needs of clients.

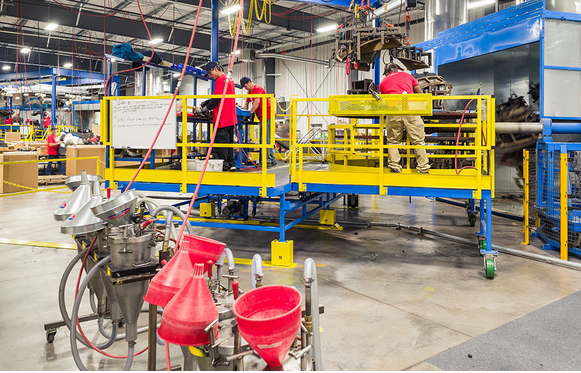

2. The procedure of Rotomolding

The procedure of rotomolding entails four phases. The 1st period is packing the mold with all the uncooked material. The second point involves warming the fungus although rotating it to spread the plastic material material uniformly, thus ensuring that the material reaches all of the aspects of the mold. Once the melting process, the mold will then be cooled and solidified, and also the concluded item is eliminated. The molding method produces high-good quality plastic-type material products which are tough, immune to wear and tear, as well as abrasions.

3. Applications of Rotomolding

Rotomolding has created a substantial effect inside the manufacturing business, and contains opened up a wide range of goods that are affordable and efficient. The procedure is utilized to manufacture various products, including boxes, playgrounds products, tanks, as well as other outside and inside products which require durability. The rotomolding process can create small or large hollow items with uniform wall structure thicknesses, which makes it ideal for a wide variety of merchandise.

4. Advantages of Rotomolding

Rotomolding has several advantages in comparison with other conventional plastic-type production processes. The initial edge is the fact that it is a cost-successful approach, so that it is a very cost-effective and finances-warm and friendly solution for creating plastic-type products in big amounts. 2nd, rotomolded goods are light in weight and, when made correctly, are equipped for an array of products without compromising toughness. Rotomolding is additionally an eco-friendly method that has no spend or convenience worries. Unlike other operations, excessive components might be used again right after crushing to create other items, developing a much more sustainable production process.

5. Future of Rotomolding

The future of rotomolding is bright, as well as the approach will continue to be used to make substantial-high quality products. The growth of the latest technology and the greater consumption of progressive layout will be the main thing on the industry’s improvement. Businesses will delve much more about the process’s customization to fulfill each client’s requires. This growth can give consumers a chance to their very own items precisely created to accommodate their distinct specifications.

Simply speaking:

Rotomolding is a superb manufacturing process that made substantial adjustments in the marketplace, delivering spending budget-friendly, tough, and eco-warm and friendly plastic-type material merchandise. Featuring its several benefits, rotomolding is growing and adjust to the industry’s requires. The near future appears vibrant for rotomolding, along with its versatility and adaptability, it may get accustomed to virtually any product that we can easily imagine.